Alumaker

So we tried Lost PLA casting with aluminum.

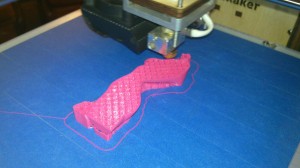

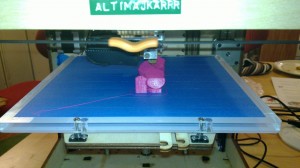

Step 1, printing a model. We took this bust from Thingiverse and printed it at pretty good quality on our Ultimaker with pink PLA.

The print took about 3 hours. Then we lowered this statue into plaster and let it set for a couple of weeks. Then this mold was heated to 100-150°C in order to dry out the plaster. This melted the PLA, so it could be poured out.

At the night of The Pouring, we started by slowly pre-heating the mold. Then the aluminum was prepared. The mold was then heated up some more in the forge, burning away residual PLA. Some minor cracks formed at this step.

Here is the mold buried in sand, while the aluminum is heated.

Molten aluminum, ready to pour.

Pouring.

Cooling.

Breaking the outer metal can that the plaster mold was contained in.

And here is the final result: